The NDC’s Technical Services Unit has more than 20 years of experience providing specialist testing services for subsea engineering and offshore decommissioning equipment. Our dedicated highly experienced technical team offer independent testing and verification to the offshore industry from our purpose built test facility in Newburgh, Aberdeenshire. Servicing both UK and international clients we provide a comprehensive range of testing equipment and bespoke services to quickly and accurately assess the reliability of components and assemblies. The testing equipment is housed in a large, hanger space with full HGV access serviced by a 2.5 ton overhead crane.

The NDC houses the most powerful industrial laser of any academic institution in the UK. The IPG YLS-15000 is specifically designed for high performance cutting in harsh environments.

- IPG YLS15000 15kW continuous wave Ytterbium fibre laser (1070nm wavelength)

- 30m 300micron process fibre

- 30m 400micron process fibre

- IPG collimators

The laser system has been used in a project proving the concept of underwater laser cutting as a viable, economic and energy efficient alternative to existing techniques. Phase II of the project is developing the technology to deliver a commercial cutting system.

The NDC’s large volume pressure vessel (1.8m x 0.75m internal) can simulate deep ocean conditions down to the equivalent of 7000m depth. The vessel also has 6 penetrator ports for hydraulic/electronic connection to the test items. This certified testing service has supported the oil and gas, research and defence sectors.

Specifications:

- Maximum pressure 700Bar

- Internal dimensions: – 750mm diameter, 1800mm depth

- Vertically orientated working chamber serviced by a 2.5T x/y axis overhead crane

- The vessel lid has 6 ports through which hydraulic and electrical connections can be made

- A stock of blank portal covers is available for issue or the specifications can be made available.

The large capacity chambers can prove system reliability for the harshest conditions with comprehensive software controlled test cycles and temperature soaks.

Specifications:

- Test space volume: 900 litre (Width 1100mm, Depth 950mm, Height 950mm)

- Temperature range: -40oC to +180oC

- Humidity range: 10% to 98% (within +10oC to +95oC temperature range)

- Temperature rate of change: 2.7oC/min. (cooling), 3.0oC/min. (heating)

- Temperature fluctuation: <+/- 0.3oC (over time); <+/-1.0oC (spatial)

- Humidity fluctuation: < +/- 3.0%

Temperature changes in the ocean and on land can affect the operation of hydraulic, mechanical, laser performance, electronic equipment and materials.

The environmental chamber simulates temperature and humidity profiles.

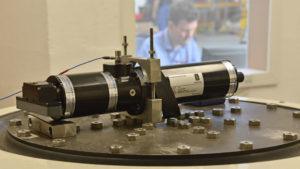

The vibration table is industry standard for automotive, aerospace and electronics testing and has been used extensively at the NDC for those industries as well as subsea technologies. It allows designs to be evaluated for shocks or mechanical resonances by carrying out automatic swept-sine resonance searching with programmable trigger level and dwell time.

Accelerated-life testing of land and air and sea transportation stresses can also be performed, as well as and shock testing, to simulate stresses from rough handling of equipment during deployment at sea.

Ling Dynamics Systems

V870-640T Vibrator

SPA 40/30K-v2 Amplifier

LDS Dactron LaserUSB Controller

ICP Accelerometers

Specifications:

- Armature diameter 640mm

- Peak sine force 33.4kN

- Random force 26.7kN

- Half sine bump force 80kN

- Useful frequency range 5 to 2400Hz

- Peak sine velocity 1.5m/s

- Peak sine and random acceleration 50g

- Displacement pk-pk 50mm

- Amplifier power 40kVA

- Maximum load 600kg

The associated software allows the following types of test:-

- Sine Sweep

- Resonance Search and Dwell

- Random

- Shock

This test equipment is industry-standard for automotive, aerospace and electronics testing. It allows designs to be evaluated for mechanical resonances by carrying out automatic swept-sine resonance searching with programmable trigger level and dwell time. Accelerated-life testing of land and air and sea transportation stresses can also be performed, as well as and shock testing, to simulate stresses from rough handling of equipment during deployment at sea.

The system is capable of performing industry standard vibration tests such as:-

- BS EN ISO 13628-6:2006

- US MIL801F

- IEC 60068-2-6

- ASTM D3580

The NDC has a substantial indoor freshwater tank capable of accommodating offshore assemblies for testing. The tank has dimensions of 5 x 5 x 5 metres and is an essential proving facility for subsea inspection equipment, ROVs and other subsea test simulations.

Our close proximity to the Ythan Estuary with a boatyard and slipway means we can offer the facilities to assist with research and development of any tidal stream-based systems (following the necessary regulatory consents).

Our in-house CNC capabilities provide our clients with significant flexibility in product development and part rework jobs, offering quick turnaround. Our CNC machining services including cutting, milling, and turning are capable of tackling most geometries and materials used in today’s industrial applications.